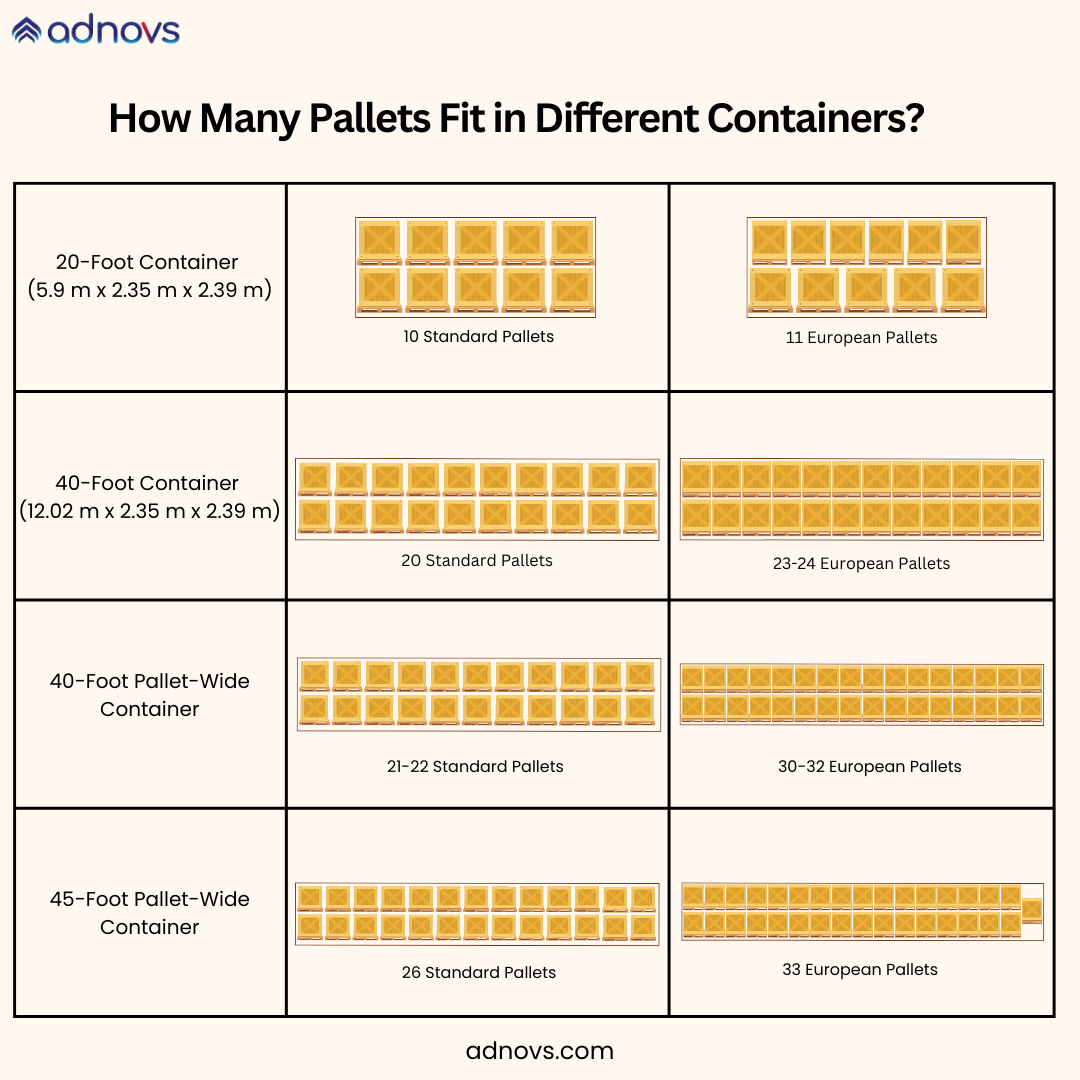

How many pallets fit in a 20ft container

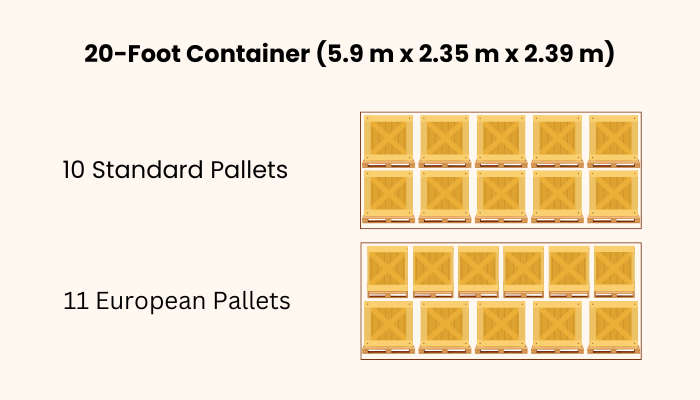

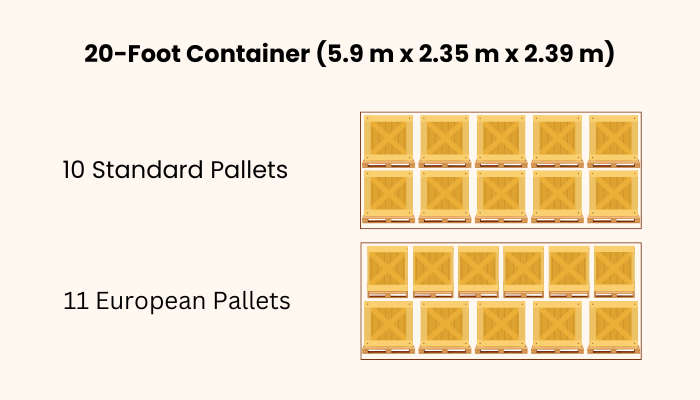

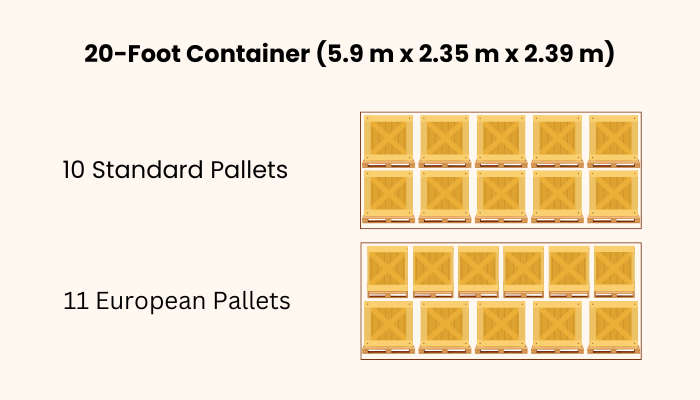

20-Foot Container:

Typically, you can fit 10 Standard pallets of 1.2 x 1.0m dimensions and 11 European pallets of 1.2 x 0.8m dimensions.

Typically, you can fit 10 Standard pallets of 1.2 x 1.0m dimensions and 11 European pallets of 1.2 x 0.8m dimensions.

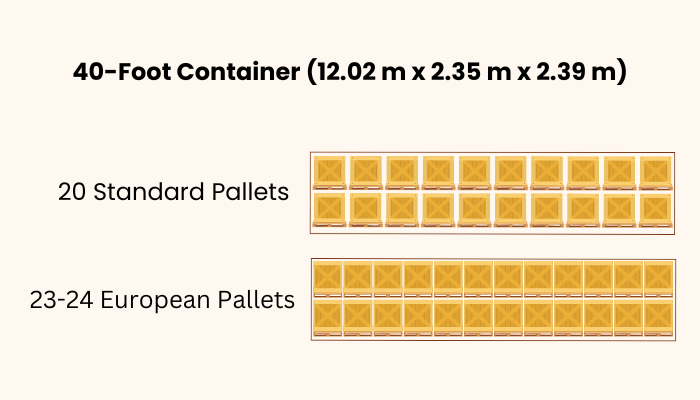

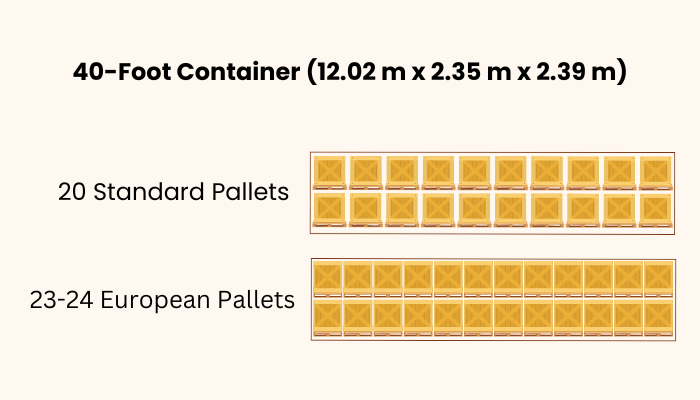

40-Foot Container Standard Containers:

You can fit 20 standard pallets and 23-24 European pallets.

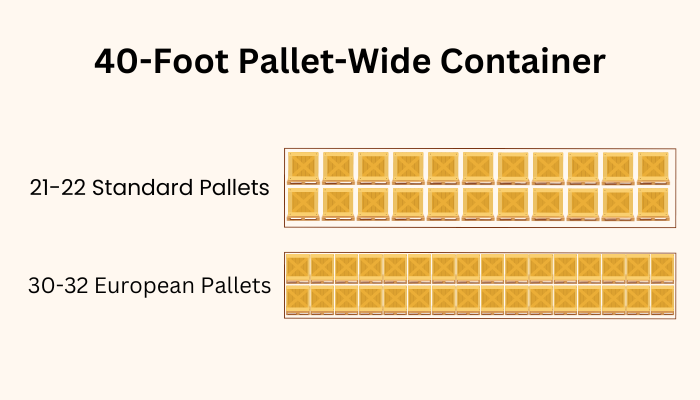

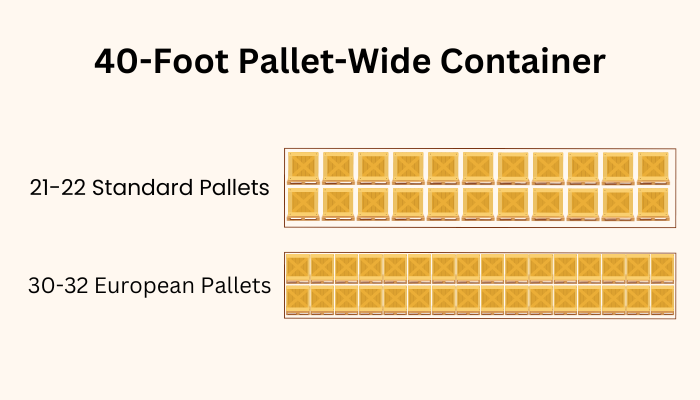

40-Foot Pallet-Wide Container:

You can fit up to 21-22 standard pallets and 30-32 European pallets.

40-Foot High Cube Container:

You can fit up to 21-22 standard pallets and 24-25 European pallets.

40-Foot High Cube Dry Container:

You can fit up to 21-22 standard pallets and 24-25 European pallets.

Understanding the number of pallets that fit into different types of shipping containers is crucial for efficient logistics and supply chain management. The overall capacity depends on the type of container and the size of the pallets used. The pallet capacities for various standard and specialized containers are given below.

The two most common pallet sizes are:

– Standard Pallets: Typically, you can fit 10 Standard pallets of 1.2 x 1.0m dimensions.

– European Pallets: You can fit 11 European pallets of 1.2 x 0.8m dimensions.

The 20-foot container is versatile and easy to handle, suitable for various goods and shipping methods. It’s cost-effective for smaller shipments and widely available globally. Its standardized design ensures compatibility, while robust construction and lockable doors offer excellent security. The compact size efficiently optimizes space for dense or heavy cargo.

– Standard Pallets: You can fit 20 standard pallets.

– European Pallets: You can fit 23-24 European pallets.

The 40-foot container is highly versatile. It can accommodate a wide range of goods, including large machinery, equipment, etc. Due to their large size, we can consolidate larger shipments instead of using multiple containers. They are easy to handle and transport and fit well into intermodal transport systems. It is a flexible and cost-effective choice for many shipping needs.

The pallet-wide container is specifically designed to maximize space for palletized goods, especially European pallets. This design reduces the need for pallet reconfiguration, saving time and labor costs. Additionally, the increased width optimizes cargo space, ensuring better utilization and reducing shipping costs per unit of cargo. The pallet-wide container also maintains compatibility with standard shipping infrastructure, providing both flexibility and efficiency for transporting palletized goods.

40-Foot Pallet-Wide Container:

Internal Dimensions: 39′ 4″ x 7′ 9″ x 7′ 10″ (12.00 m x 2.35 m x 2.39 m)

Internal Dimensions: 44′ 4″ x 8′ x 9′ 6″ (13.55 m x 2.44 m x 2.89 m)

High cube containers offer an extra foot of height, increasing capacity and optimizing space for bulky or voluminous cargo. They reduce shipping costs by requiring fewer containers and are versatile for various goods. Compatible with standard shipping infrastructure, they provide enhanced security and are ideal for modifications like mobile offices or storage units.

40-Foot High Cube Container:

Internal Dimensions: 39′ 6″ x 7′ 8″ x 8′ 10″ (12.02 m x 2.34 m x 2.69 m)

American Pallets: Typically 21-22 pallets

European Pallets: 24-25 pallets

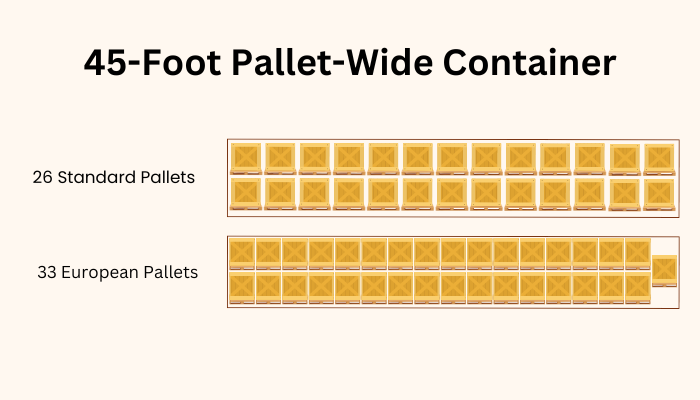

45-Foot High Cube Container:

Internal Dimensions: 44′ 4″ x 7′ 8″ x 8′ 10″ (13.55 m x 2.34 m x 2.69 m)

High cube dry containers offer an extra foot of height, providing increased capacity for light, bulky, or voluminous cargo. They optimize space usage, reduce shipping costs by requiring fewer containers, and are versatile for a wide range of goods. Compatible with standard shipping infrastructure, they ensure enhanced security with robust construction and lockable doors. These containers are also ideal for modifications like mobile offices or storage units.

40-Foot High Cube Dry Container:

Internal Dimensions: 39′ 6″ x 7′ 8″ x 8′ 10″ (12.03 m x 2.35 m x 2.70 m)

American Pallets: Typically, you can fit up to 21-22 pallets.

European Pallets: you can fit up to 24-25 pallets.

45-Foot High Cube Dry Container

Internal Dimensions: 44′ 4″ x 7′ 8″ x 8′ 10″ (13.56 m x 2.35 m x 2.70 m)

American Pallets: Typically, you can fit up to 26 standard American pallets.

European Pallets: You can fit up to 33 European pallets.

Smart Freight Centre (SFC) is a leading organization dedicated to supporting companies to become more environmentally friendly.

They offer two membership levels:

This level acts as a foundation and we get access to:

In addition to everything included in the Base membership, the Premium level offers:

Choose the membership level that fits your needs and budget. Start with the Base membership for basic green logistics practices. As your company grows and your commitment deepens, you can explore the Premium membership for further support and opportunities to lead the way in green logistics.

الخدمات اللوجستية الخضراء تعني ببساطة تقديم الخدمات اللوجستية دون الإضرار بالبيئة. إنهم يهدفون إلى تقليل آثار الكربون والمشاركة في الممارسات المستدامة طوال الرحلة اللوجستية.

تشمل الأسماء الأخرى للخدمات اللوجستية الخضراء الخدمات اللوجستية الإنسانية، والخدمات اللوجستية الجيدة، والخدمات اللوجستية البيئية، والخدمات اللوجستية المستدامة، وما إلى ذلك.

لا تهتم الخدمات اللوجستية التقليدية بالاستدامة أو التدابير الصديقة للبيئة. إنهم يستخدمون الكثير من الطاقة، ويولدون الكثير من النفايات، ويتركون بصمة كربونية كبيرة وراء خدماتهم.

اليوم، لم تعد الخدمات اللوجستية الخضراء مجرد كلمة، بل هي مفهوم مهم للغاية يجب على كل شركة تنفيذه. يمكن أن تكون بمثابة مبادرة المسؤولية الاجتماعية للشركات (CSR) للشركة ويمكن أن تكون بمثابة تمييز عن المنافسين. تدرك الشركات في جميع أنحاء العالم الآن أهمية الخدمات اللوجستية الخضراء والممارسات المستدامة، والتي ليست فقط الأفضل للبيئة ولكنها مفيدة لأعمالهم أيضًا.

من الضروري اعتماد الخدمات اللوجستية الخضراء وممارسات إدارة سلسلة التوريد الخضراء نظرًا لأن بيئتنا عرضة لتحديات مثل تغير المناخ ونفاد الموارد. إن اعتماد الخدمات اللوجستية الخضراء يجعل عملياتك اليومية تسير بسلاسة مع الحفاظ على كوكبنا آمنًا.

الخدمات اللوجستية الخضراء تعني أن العمليات اللوجستية تتم دون الإضرار ببيئتنا. أنها تنطوي على تنفيذ ممارسات صديقة للبيئة في جميع العمليات في مجال الخدمات اللوجستية وإدارة سلسلة التوريد من نقطة المنشأ إلى نقطة الاستهلاك.

وباعتبارها أكبر وسيلة نقل، فإن الخدمات اللوجستية لها تأثير كبير، مما يجعل من الضروري التحول نحو الخدمات اللوجستية الخضراء.

باختصار، أصبحت الخدمات اللوجستية الخضراء حاسمة لأي عمل بما في ذلك الخدمات اللوجستية وإدارة الإمدادات لأنها لا تساعد فقط في حماية البيئة ولكنها توفر أيضًا فوائد اقتصادية للشركات. يجب على الشركات الاستفادة من ممارسات الاستدامة كجزء من عملياتها من أجل الاستعداد بشكل أفضل للتغيرات في عالم الأعمال. وهذا لا يجعلهم أفضل في التعامل مع التحديات فحسب، بل يساهم أيضًا في بناء حلول سلسلة التوريد العالمية التي تكون صديقة للبيئة وقوية.

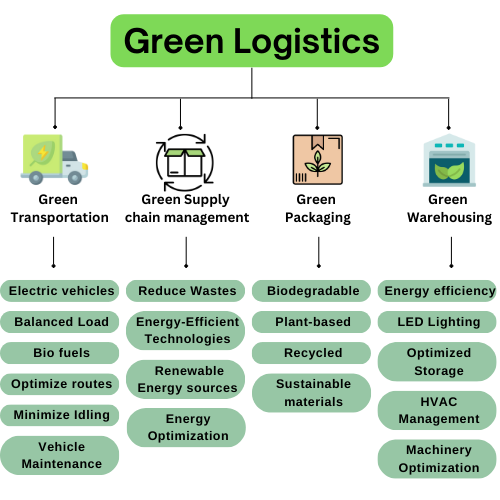

يمكن تحقيق الخدمات اللوجستية الخضراء من خلال ممارسات صديقة للبيئة ومستدامة في صناعة الخدمات اللوجستية.

يمكن تحقيق النقل الفعال من خلال ،

تشمل ممارسات إدارة سلسلة التوريد الخضراء ما يلي:

استخدم مواد تعبئة صديقة للبيئة مثل المواد النباتية، والمعاد تدويرها، والقابلة للتحلل. لا تستخدم أبدًا المواد البلاستيكية أو الورق المقوى غير القابلة للتحلل للتغليف. تأكد من تقليل الاستخدام المفرط لمواد التعبئة والتغليف دون المساس بجودة التعبئة.

التغليف الصديق للبيئة يقلل من النفايات الإجمالية والحفاظ على الموارد. فهو يساعد على منع التلوث في البيئة، ويدعم عمليات إعادة التدوير، ويقلل من البصمة البيئية.

يتضمن التخزين الأخضر الاستخدام الأمثل لمساحة تخزين المستودعات والآلات مما يقلل من العمليات غير الضرورية وبالتالي يقلل من انبعاثات الكربون. يضمن التخزين الأخضر أن تكون مساحة التخزين موفرة للطاقة. يساهم استخدام إضاءة LED وأنظمة التدفئة والتهوية وتكييف الهواء (HVAC) الموفرة للطاقة وإطفاء الأضواء والآلات في حالة عدم استخدامها في كفاءة استخدام الطاقة كما يوفر فوائد اقتصادية.

أحد التحديات الرئيسية التي تواجهها هو الاستخدام الواسع النطاق للوقود الأحفوري في العمليات اللوجستية. وهذا لا يشكل تهديدات بيئية فحسب، بل يشكل أيضًا تهديدات اقتصادية بسبب تقلب أسعار الوقود.

ويمكن حل هذا التحدي عن طريق،

والآخر لا يتبع القواعد واللوائح البيئية. قد يؤدي اتباع هذه القواعد إلى تكاليف إضافية ولكن عدم اتباعها يسبب تهديدات بيئية ومخاطر قانونية ومخاطر تتعلق بالسمعة.

ويمكن حل هذا التحدي عن طريق،

على عكس الخدمات اللوجستية العادية، تتضمن الخدمات اللوجستية العكسية حركة البضائع من نقطة النهاية إلى نقطة البداية. تحدث هذه العملية إذا أراد العميل إرجاع المنتجات، أو لأغراض مثل إعادة التدوير أو إعادة التصنيع أو التخلص منها.

بعد تفشي فيروس كورونا (COVID-19)، بدأ الناس في الشراء عبر الإنترنت في الغالب، مما يسهل إرجاع المنتجات إذا لم تكن راضية. يقوم الأشخاص بطلب المنتجات وإعادتها إذا كانوا لا يريدونها. تتضمن عملية العودة هذه الكثير من انبعاثات الكربون

A letter of credit (LC) is widely used in international trade, which is a financial instrument issued by a bank on behalf of the buyer (importer). This acts as an intermediary between buyer and seller in the transactions.

If the buyer and seller decide to use the letter of credit as the method of payment between them, The bank will pay the amount required to the seller, on behalf of the buyer. LC includes a set of terms and conditions to be met by the seller to get paid. The terms and conditions include details like the amount of the credit, the expiry date, the shipping documents required, and any other conditions agreed upon by the buyer and seller.

Let’s discuss Negotiable vs Non Negotiable bill of lading.

Personal Protective Equipment(PPE) is used by employees in warehouses for their well-being and for protecting themselves from accidents and injuries. Warehouses may involve various operations with potential hazards, so using the right PPE is essential for safety.

Some Personal Protective Equipment(PPE) used in a warehouse are listed below,

To know more tips for warehouse safety, visit the blog 60+ warehouse safety tips

We have provided 60+ safety tips and suggestions for your warehouse operations below.

1. Emphasize safety in your warehouse operations to prevent any accidents or injuries.

2. Check your work area thoroughly before starting the work to ensure the workspace is safe.

3. Dispose of waste promptly for cleanliness and to avoid problems like tripping.

4. Maintain a clean and hygienic environment in the warehouse. Provide cleaning equipment like brooms, dust pans, trash cans, etc.

5. Dispose of broken pallet pieces in assigned bins for a safe workspace.

6. Place separate bins for cardboard and other trash for efficient waste management and recycling.

7. Ensure proper dock door seals to avoid water leaks and maintain a dry working area.

8. Make sure ergonomic mats are well secured to the floor. ergonomic mats are used for reducing fatigue.

9. Keep equipment charging stations at a safe location to avoid fire hazards while charging.

10. Place PPE (Personal Protective Equipment) dispensaries at designated locations so workers can easily access safety gear. Safety gears include gloves, safety glasses, safety helmets, high-visibility vests, etc.

11. Check for the air quality inside the warehouse to ensure workers’ well-being.

12. Before turning at corners, ensure no others are coming to avoid collisions

13. Use a light when loading trailers so that others see you and avoid collisions.

14. Wear bright color vests so that the workers are visible to each other.

15. Always keep an eye on your walking or driving path to avoid collisions.

16. Consider using mirrors to enhance visibility at intersections and corners.

17. Make sure the signages are not damaged and visible.

18. Place anti-slippery mats in wet and slippery places.

19. Use safety shoes to protect your feet from injuries and prevent slipping.

20. Don’t use your back for lifting heavy objects instead bend your knees and use your leg muscles to avoid back injuries.

21. Use a “heavy” label for heavy items and “Fragile” for delicate items to notify workers for safe handling.

22. Always ask for help from co-workers if you need help lifting items.

23. Train the employees on proper lifting techniques.

24. Place heavier items at the bottom and lighter ones at the top to maintain the stability of stacks and prevent them from collapsing.

25. Close and secure boxes properly, using strong tape to avoid opening or spilling.

26. Distribute weight inside the boxes evenly.

27. Clean and remove leftover pallets or debris in the storage space before placing new products.

28. Make use of ladders for taking items at a height to avoid falling and accidents.

29. If the storage contains hazardous materials, provide instructions on how to store, handle, and dispose of them.

30. If the storage contains confidential materials, ensure security to avoid unauthorized access.

31. Don’t be distracted while using powered equipment to avoid accidents. For eg. Avoid consuming food during those times

32. You should be careful when unpacking boxes to avoid cuts or injuries.

33. Consider wearing good-quality gloves to protect your hands from injuries.

34. Stay away from conveyor rollers to avoid injuries by contact with moving parts.

35. Use fitted clothes as loose clothes may get caught in machinery.

36. Avoid sitting or leaning on conveyor belts to avoid injuries.

37. Tie up or keep hair above the shoulder to avoid injuries by hair caught in machinery.

38. Avoid repairing equipment if you are not trained to do so to prevent damage and injuries.

39. Regularly check and repair pieces of equipment.

40. Properly store fall protection harnesses when not in use to ensure their safety and accessibility when in need.

41. Clean protection harnesses to maintain their condition.

42. Keep your 5 body parts in contact with the PIT (Powered Industrial Truck) to maintain balance and avoid falling. The 5 body parts include 2 hands, 2 feet, and knee or elbow.

43. Teach employees how to use tagout equipment.

44. Designate a separate area for keeping damaged tools and equipment to avoid using them.

45. Train employees on how to use equipment properly.

46. Train employees how to act effectively in case of sudden fire.

47. Place cold weather gear strategically to be easily accessible in case of emergency.

48. Ensure employees are aware of emergency exits and evacuation procedures.

49. Provide emergency instructions on equipment for quick reference at critical times.

50. Promptly notify the safety team if you see any unknown or hazardous things.

51. Avoid traditional methods of reporting safety hazards. Use digital ways to ensure quick reporting and resolving problems like using mobile apps that facilitate quick reporting with added photos, descriptions, places, etc.

52. Train employees on how to act in emergencies.

53. Make first aid kits available and easily accessible. Teach employees how to use them.

54. Analyze the various warehouse tasks and make sure to minimize physical strains.

55. Ensure the emergency eye wash stations are available and functioning properly.

56. Encourage daily stretching exercises that help in flexibility and prevent musculoskeletal problems.

57. Remind the workers to drink water often to avoid dehydration.

58. Fasten and secure loose cables in the warehouse. This prevents fire hazards and tripping of workers due to the cables lying on the floor.

59. Protect hazardous machines using safety guards. This helps in keeping people away from the machines.

60. Schedule regular meetings to discuss and resolve any safety concerns.

61. Check and maintain the speed bumps in the warehouse parking lot in good condition.

62. Evaluate the workspace focusing on the 5S principles and update accordingly. 5S stands for Sort, Set in order, Shine, Standardize, and Sustain which helps in the efficiency, organization, and safety of the workspace.

63. Utilize EHS (Environmental, Health, and Safety) software to monitor and handle safety-related tasks.

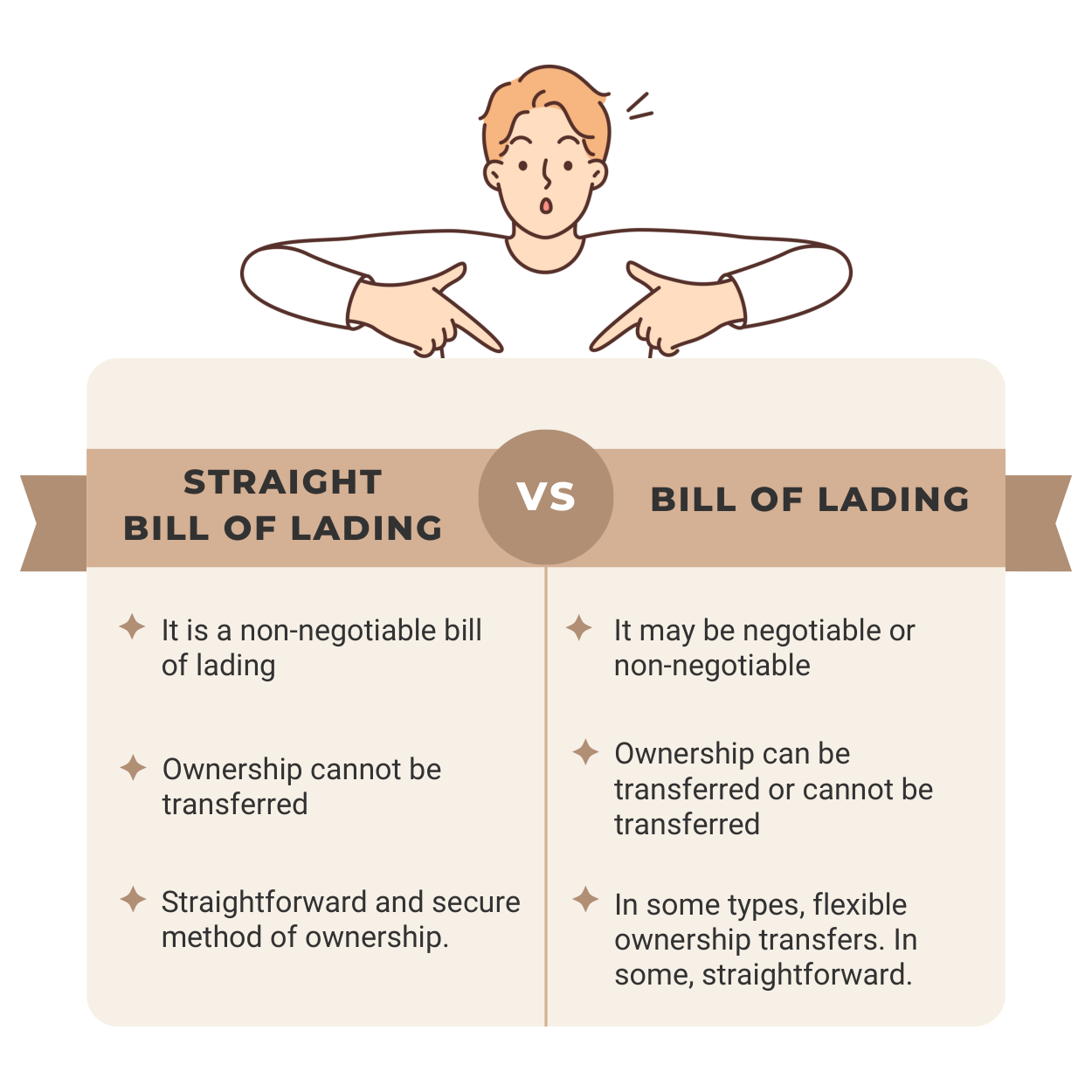

Let’s discuss Straight bill of lading vs bill of lading. A Straight Bill of Lading (BoL) and a Bill of Lading (BoL) are terms often used interchangeably, but they refer to different aspects of the same shipping document.